New construction of a bakery with café

More light and air for traditional craftsmanship

A tradition of craftsmanship since 1886 – Schäfers bakery in Chemnitz is the oldest local business in Chemnitz Rabenstein and has been delighting customers with baked goods made according to family recipes for decades. The bakery now supplies 20 branches and has over 120 employees. The company's growth necessitated a site expansion to provide more space and optimal production conditions. In 2021, the expansion began with the construction of a larger production hall, and a café. The big challenge here: the bakery generates a lot of heat, which conventional ventilation units with extractor hoods could not cope with. A combination of roda and LAMILUX products now represents the optimal solution.

Brief description

Location: Schäfers Backstube GmbH

Project: Installation of a ventilation system

Period: Spring/Summer 2021

Object installed: 7 double flap fans of type MEGAPHOENIX including insect protection grid, 13 louvre fans of type SMOKEJET, 6 LAMILUX Rooflight F100 units including insect protection grid and deciduous tree sheeting, 46 metre continuous rooflight with arched design

Requirements for the systems

For baked goods to be perfect, the dough must be made to the exact degree, in winter as well as in summer. The radiant heat sometimes generated temperatures of over 50 °C in the old production hall, which posed great challenges for production, especially in the very warm months between May and September. To avoid this happening in the new building, the most important requirement for the new production hall was permanently optimal and efficient ventilation, as well as constantly pleasant temperatures for workers in the bakery.

In order for a food business to be allowed to sell the products it produces, hygiene standards must also be met. These standards are basically regulated according to EU hygiene law under EU Regulation 852/2004. This meant that we had to ensure that no insects could get into the production hall and thus into the flour or dough.

LAMILUX and roda

the best of two worlds

The perfect roda solution resulted from the optimally matched combination of roda and LAMILUX products. A sensible addition and combination of the systems now leads to optimal light and air conditions in the new building of Schäfers Backstube. The LAMILUX systems offer optimum daylight illumination in the sales area in combination with heat and insect protection through the deciduous tree sheeting system and the integrated insect protection grid. The roda systems in the production hall ensure permanent and hygienic air and heat exchange in production, with the supply air systems in the façade and the rainproof ventilation systems on the roof.

The roda systems

With six MEGAPHOENIX multipurpose fans installed above the bakery and another one above the washroom, permanent natural air exchange is guaranteed in the production hall. The newly installed systems ventilate at 90° with the entire aerodynamically effective opening area.

When it starts to rain, the hoods close by means of a rain sensor and the side flaps of the multi-purpose fans open, thereby ensuring air exchange and heat extraction in production. Sufficient supply air must also be provided wherever air is discharged. With 13 SMOKEJET type louvre fans, nine of which are standalone and four of which are interlinked and integrated into the façades.

The position of the multipurpose fans always determines the position of the SMOKEJET. This means that when the external hoods of the MEGAPHOENIX are opened, the 230 V supply air drives are activated and the supply air groups of the SMOKEJET also open fully. If the exhaust air units are completely closed, the supply air units also close. If it starts to rain or if the wind is too strong, the open fair weather position is closed and, at the same time, the rainproof ventilation position opens and the supply air louvres move to the 50 percent position.

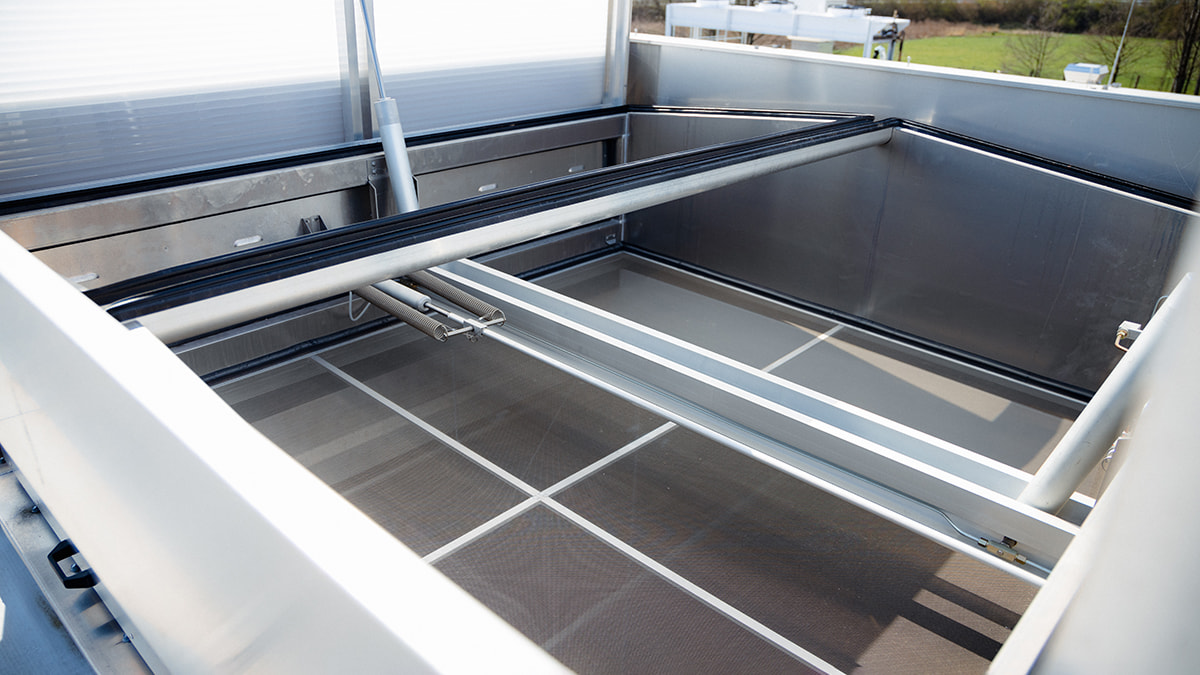

Stainless steel insect protection grids installed on the SHEVS and ventilation units prevent insects from entering and ensure the high hygiene standards. The insect protection grids of the multipurpose fans are full-surface and have been integrated as drawer systems. This allows access from the outside and easy cleaning of the grids.

The SHEVS and ventilation units are supplemented by an approximately 46-metre-long continuous rooflight that floods the production hall with healthy daylight and saves on electricity for artificial lighting during the day. Five LAMILUX Rooflight F100 units also provide the sales rooms with sufficient daylight. The rooflights are equipped with a 230 V motor and an insect protection grid. In addition, a deciduous tree sheeting system provides optimum thermal protection for the rooflights. A rooflight was implemented as a roof access hatch in order to grant access to the roof.

A positive side effect: The energy-free ventilation provided thanks to the thermal lift and illumination of the hall with daylight save Schäfers Backstube additional operating costs.

That’s what our customer says

In our old bakery, we generated considerable heat, which meant that it was sometimes hotter than 50 °C in production. Conventional ventilation units with extraction and extractor hoods above the ovens could not compensate for such a build up of heat.

roda ventilation units now ensure a very even room temperature in our new production building thanks to a natural chimney effect. This has a positive effect on our doughs, as we have a certain consistency in quality and do not have to adjust our dough temperatures as often as we had to in the old building. The continuous rooflight also floods our production hall with daylight and provides pleasant lighting conditions for our employees.

From planning to execution, we were impressed by roda's professional project management and support.