New construction of a sewage sludge incineration plant

Sustainability thanks to roda's innovative ventilation solution

EEW Energy from Waste operates the largest and most modern plant in Germany. With thirty years of experience in waste recycling and disposal, they lay the foundation for Lower Saxony's first mono-incineration plant. At the Helmstedt site, 160,000 tons of sewage sludge (525,000 tons of waste and residual materials) are to be incinerated to 15,000 tons of ash each year. The mono-incineration of sewage sludge enables a phosphorus recovery rate of over 80 percent from sewage sludge in downstream processes.

Brief description

Location: EEW Energy from Waste GmbH Helmstedt

Project: Construction of a new incineration plant

Period: Year 2022

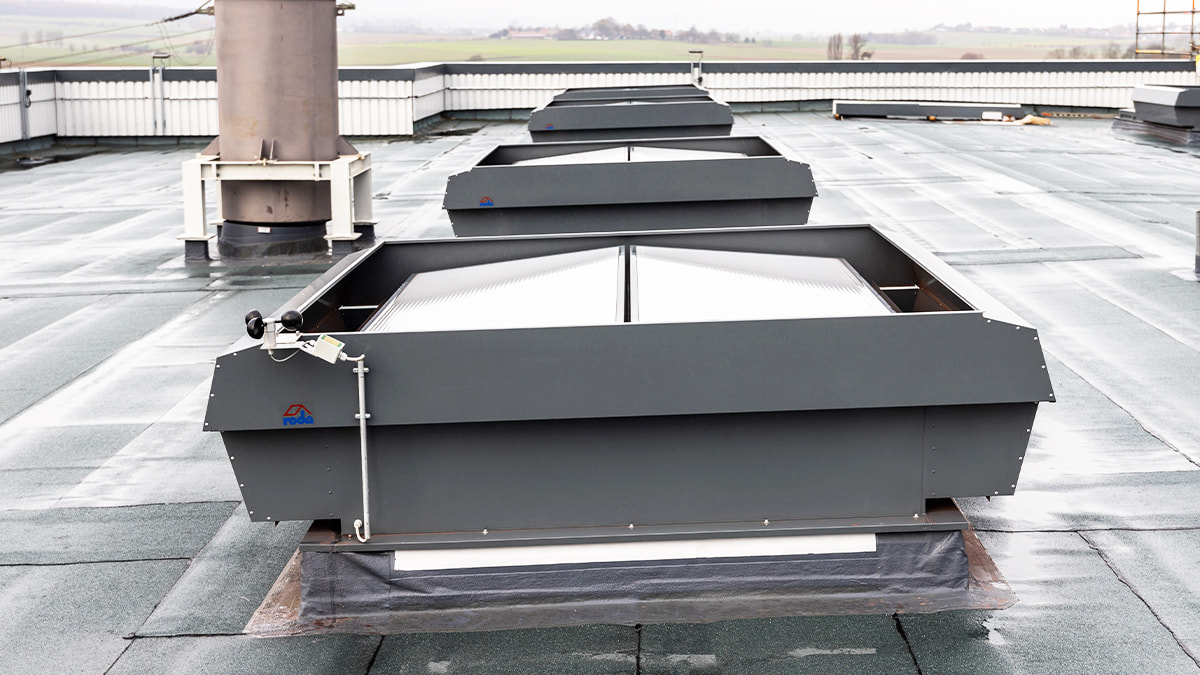

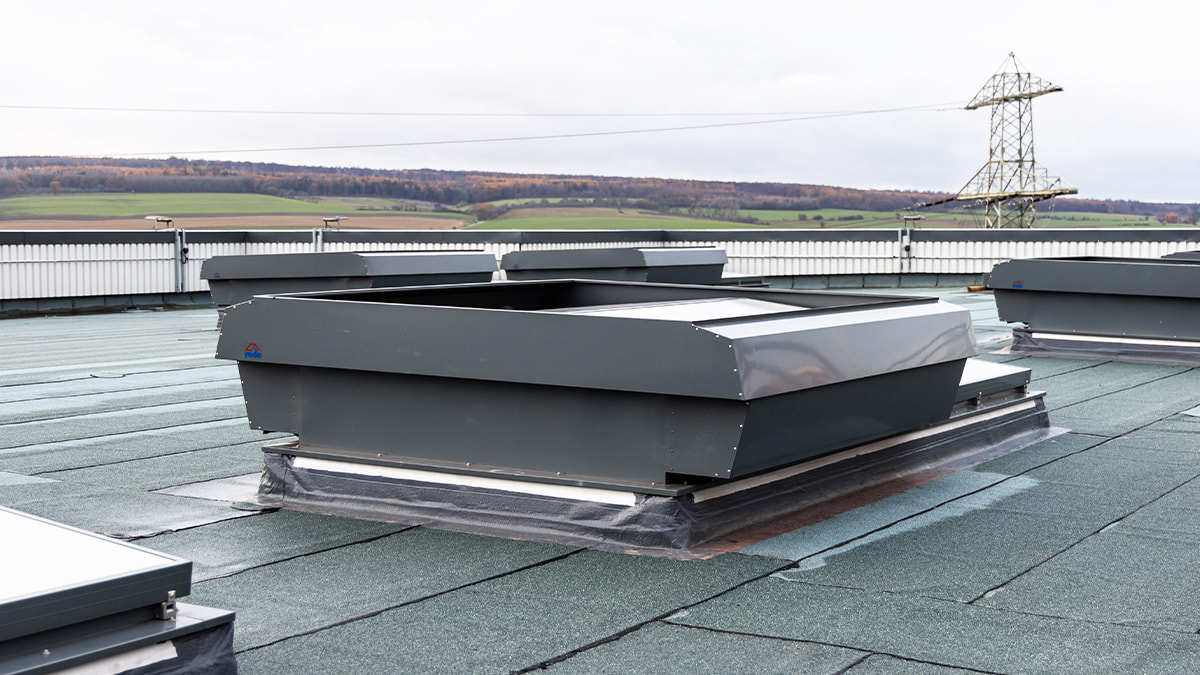

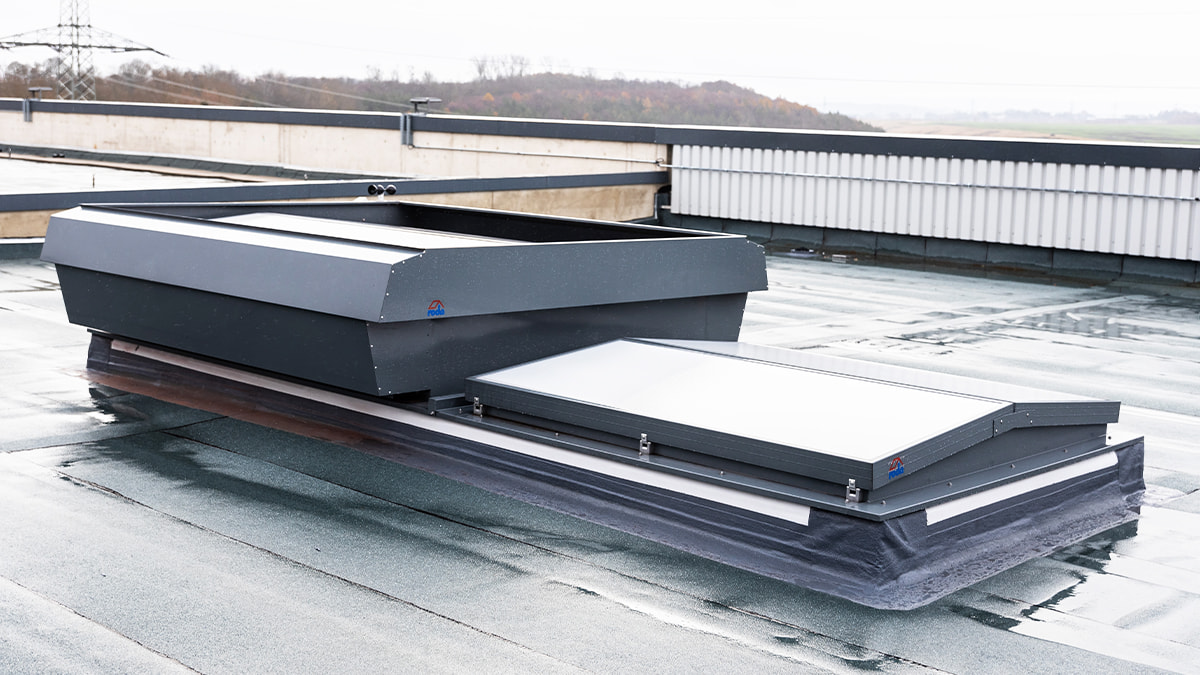

Installed products: 5 supply air louvres with warm air supply including sound-absorbing screens and bird protection, 5 supply air louvres without warm air supply including sound-absorbing screens and bird protection, 5 warm air admixtures for winter operation, 8 multi-purpose ventilators type MEGAPHÖNIX, 8 double flap ventilators type PHÖNIX as pure heat extraction surface

EEW Energy from Waste

Pioneering Work in Waste Management

The Challenge: Efficient and Safe Ventilation in a Demanding Industrial Environment

The incineration of sewage sludge requires sufficient fresh air supply in the boiler house. However, the heat output from the boiler house must be reliably dissipated. This is where roda's ventilation technology comes into play, ensuring that the temperature always remains between 6 - 40 °C to avoid malfunctions or damage to the facilities.

The Black Box: Automated Control for Optimal Performance and Efficiency

Our solution is a highly complex control system that operates in the background and can be easily operated by the user via a touch panel. The Black Box automates the control of all processes that run in the background and switch the devices on or off. Temperature sensors inside and outside monitor the temperature, while stored cases control the supply and exhaust air for summer and winter operation. The CO2 trigger also takes place via the Black Box, which activates emergency release stations in the hall. This system eliminates human error and increases the performance and efficiency of the plant.

The roda systems

Efficiency and Performance: The Hallmark of roda

Our innovative ventilation solution ensures optimal air exchange in complex technical environments. This consists of ten supply air louvres with sound-absorbing screens and bird protection grilles, eight large multi-purpose ventilators of the MEGAPHÖNIX type and eight double-flap ventilators of the PHÖNIX type. Immediately behind the supply air openings is an area with fittings, pipelines and measuring points. To prevent this area from being affected by frost damage at low temperatures, we have developed a special warm air admixture system. This consists of five systems that have a pipe system suspension and an axial fan. When the supply air is cold (up to -10 °C and max. 16,000m³/h), these systems suck hot air from the ceiling (max. 40 °C) and blow it as a warm air mixture (max. 8,200m³/h, max. 40 °C) in front of the supply air opening. To ensure the longevity of our devices even under the demanding conditions in a boiler house, all devices are equipped with a C4 corrosion class coating. This coating makes the devices extremely resistant and durable.

Safety in Case of Fire

In the event of a fire, our ventilation solution reacts quickly and reliably: The ventilators switch off, the emergency sensors trigger and the smoke and heat extraction systems (RWA systems) open. In addition, eight fixed devices of the PHÖNIX type act as pure heat extraction surfaces (meltable surfaces) to meet the requirements of the fire protection concept.

That’s what our customer says

The ventilation solution from roda has exceeded our expectations. It has helped us to increase the efficiency of our mono-incineration plant and at the same time ensures the safety and longevity of our facilities. We appreciate roda for their professionalism, their tailored solutions and their outstanding service.