Rigid smoke curtains

Greater fire safety in buildings

By far the greatest danger in a fire is not the development and spread of the fire, but the rapidly spreading smoke gases. In order to prevent the spread of smoke in the building in the event of a fire, it is necessary to form smoke compartments in buildings. This is particularly important for buildings with a high volume of people, such as large event venues, or in the industrial sector, where the smoke would cause less damage to people than to property due to the high room height.

If the smoke compartments are not structurally ensured, they can be formed via smoke curtains. Smoke curtains counteract the lateral flow of smoke and hot, toxic fire gases: In the event of a fire, the smoke curtains drop and channel the smoke to confine it to a specific section area. This means that people can be safely evacuated from the building and the fire brigade can quickly locate the source of the fire thanks to better visibility.

Smoke curtains provide greater safety

This is how smoke curtains work: In large-area halls, no significant overpressure can build up under the roof in the initial phase of the fire. However, this is crucial for the effectiveness of a natural smoke and heat exhaust ventilation system. The rising smoke gases spread under the roof. They cool down and flow back down in the form of smoke rolls, where they become a life-threatening hazard near the ground.

Smoke curtains divide a hall into several smoke compartments and thus prevent horizontal smoke spread in the roof space. In addition, the curtains are also used for targeted smoke control.

The dimensioning of a natural smoke exhaust ventilation system according to DIN 18232-2 requires that the smoke compartments are not larger than 1,600 m² or are divided by smoke curtains into areas with a maximum of this size. The distance between the smoke curtains or between the wall and the smoke curtain must not exceed 60 metres. Further subdivisions (e.g. closed beams) within the smoke compartments have no influence on the dimensioning.

Area of use

- Industrial halls

- Shopping centres

- Event rooms

- Commercial construction

- Stadiums

- Car parks / underground garages

Advantages of the product

Why SMOKE CURTAINS?

- Prevention of horizontal smoke propagation

- Targeted smoke control (channelling)

- Quick localisation of the source of the fire

- Safety for humans and animals

- Damage prevention for goods

- Reduced SHEV area

- More effective smoke extraction by reducing the room volume

- Significant reduction of the supply air area

- Simple and safe assembly

Technical details of the product

Smoke curtains

Designs

roda smoke curtains are made of flame-resistant, tightly woven glass fibre material. The lightweight housing of the smoke curtains is made of galvanised steel sheets, anodised aluminium alloy or colour-coated to match the design. Smoke curtains restrict the spread of smoke to a defined area in the event of a fire.

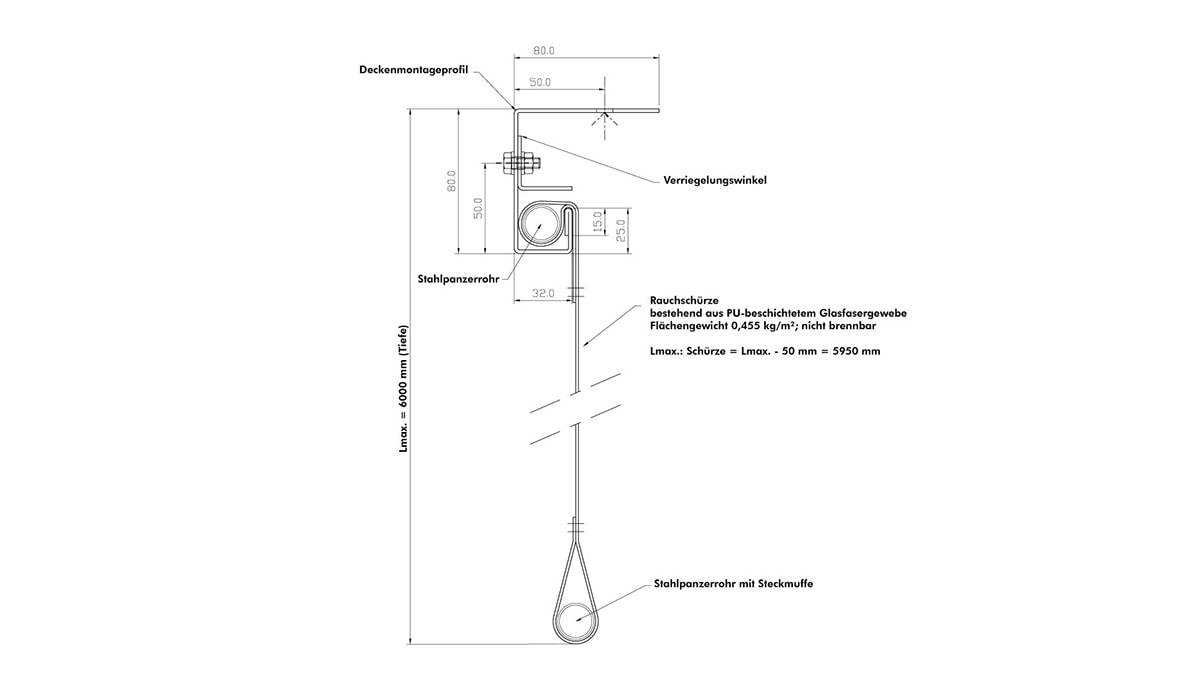

Rigid smoke curtain SMOKETEX

The roda smoke curtain “SMOKETEX” is a rigid smoke curtain made of polyurethane-coated, flexible glass fibre fabric with grey aluminium pigmentation. This fabric with a thickness of approx. 0.40 mm has a base weight of 0.455 kg/m² ±10%. The standard smoke curtain consists of vertically arranged individual elements that are sewn together with a non-combustible yarn for a maximum curtain area of 45.00 m². Individual curtains are available in widths of between 800 mm and 5,950 mm and can be extended horizontally to the maximum curtain area by means of push buttons, depending on the design. The C-shaped ceiling mounting profile consists of a multi-folded, 2 mm thick hot-dip galvanised steel sheet.

The SMOKETEX rigid smoke curtain meets the requirements for CE marking in accordance with Annex ZA3 of DIN EN 12101-1. For the conformity assessments, the procedures specified in the standard were carried out. The certified smoke curtain was tested at a temperature of 620 °C for 151 minutes, is smoke-tight according to the test report and has received the classification designation “D150” due to its compliance with DIN EN 12101-1. Upper and lateral gap dimensions are stated as 0 mm.

Rigid smoke curtain of type RST 73

- Hanging: Glass filament fabric, non-combustible according to DIN 4102-2 A2 / AbZ

- Design: Overlapping hangings. Drop profile, galvanised flat steel or galvanised round tube

- Installation: Ceiling mounting profile, with galvanised steel sheet

- Size: up to 100 x 8 m

- Classification: D 60 / DH 60

- Authorisation: Z-78.9-75 / Z-56.4211-957, CE-certified according to EN 12101-1

Rigid smoke curtain of type RST 73.1

- Hanging: Glass filament fabric, non-combustible according to DIN 4102-2 A2 / AbZ

- Design: Hanging top and bottom with hemstitch for 42 mm tube

- Installation: Wall mounting, with galvanised steel sheet

- Size: up to 100 x 8 m

- Classification: D 60 / DH 60

- Authorisation: Z-56.4211-957, CE-certified according to EN 12101-1

Rigid smoke curtain of type RSS 74

- Hanging: Glass filament fabric, non-combustible according to DIN 4102-2 A2 / AbZ

- Design: free-falling, also currentless by means of gravity

- Drive: Tubular motor 24V standard or fail-safe, tubular motor 230V standard or fail-safe

- Mounting: on the ceiling, on the wall, in the reveal

- Size: Housing 150 x 150 mm up to system size 6 x 3 m, housing 230 x 250 mm up to system size 15 x 6 m, max. system size on request

- Construction type: ASB 1 - ASB 4

- Classification: D 60 / DH 60

- Authorisation: Z-78.9-76 / Z-56.4211-957, CE-certified according to EN 12101-1

Installation

Our roda smoke curtains are characterised by simple assembly, which guarantees fast and, above all, safe installation. The installation of our roda smoke curtains is carried out on site with pre-punched ceiling mounting profiles made of steel sheet. For the ceiling fastening, only means approved by the building authorities under fire exposure may be used.

Steel tubes are pushed into the sewn-in pockets of the curtain material and the lower pipes are connected with push-in sleeves. The upper tube is used for fixing to the ceiling profile, whereby the locking brackets screwed to the mounting profile prevent the curtain from slipping out. The lower tube also serves to weigh down the smoke curtain.

In order to prevent deflection of the smoke curtain and to neglect gaps, our smoke curtains are

- connected to each other by push buttons,

- to be placed between double-sided brackets,

- to be connected to the lower edge of the single bracket, or

- to be fixed in the lower corner area in case of masonry projection.

Reliable partner in case of emergency

Our roda smoke curtains are made of flame-resistant, tightly woven glass fibre material. International and national test certificates confirm the excellent properties of the smoke curtain material. Constant production controls guarantee the highest level of consistent quality. Our professionals at roda will gladly and competently advise you on the planning of smoke curtains in your building – for optimum fire, smoke and fire protection as well as safety for people and animals.