Mechanical ventilation

The air exchange rate in a building is of great importance. It not only ensures a pleasant indoor climate, but also prevents structural damage caused by condensation, for example. Generally, a distinction is made between two types of air exchange: free ventilation and mechanical ventilation.

In new buildings with airtight construction, there is no air exchange via building leaks, which is why regular intermittent ventilation or mechanical ventilation is recommended to ensure good indoor air quality. In industrial buildings or production facilities where, in addition to warm air, mainly steam or exhaust gases are produced, regular intermittent ventilation is not always practicable. To control these circumstances, we rely on mechanical ventilation.

Central ventilation system

A distinction is made between exhaust air systems, ventilation systems and aeration and deaeration systems. An exhaust air system is used in heating plants or as a machine extraction system to convey the exhaust air to the outside through a central ventilation unit. A ventilation system supplies working areas or machines with fresh or cooling air via a duct system. With a central aeration and deaeration system, fresh air is fed into the building via a duct network and, at the same time, the same amount of exhaust air is discharged from the building.

A ventilation system has two ventilators, each of which conveys the outside air and the exhaust air. Either the two ventilators are compactly installed in one ventilation unit or arranged separately in a supply air unit and an exhaust air unit. However, central ventilation systems require a considerable amount of space and are mostly installed on roofs, which is why special measures are required with regard to sound insulation and possibly fire protection.

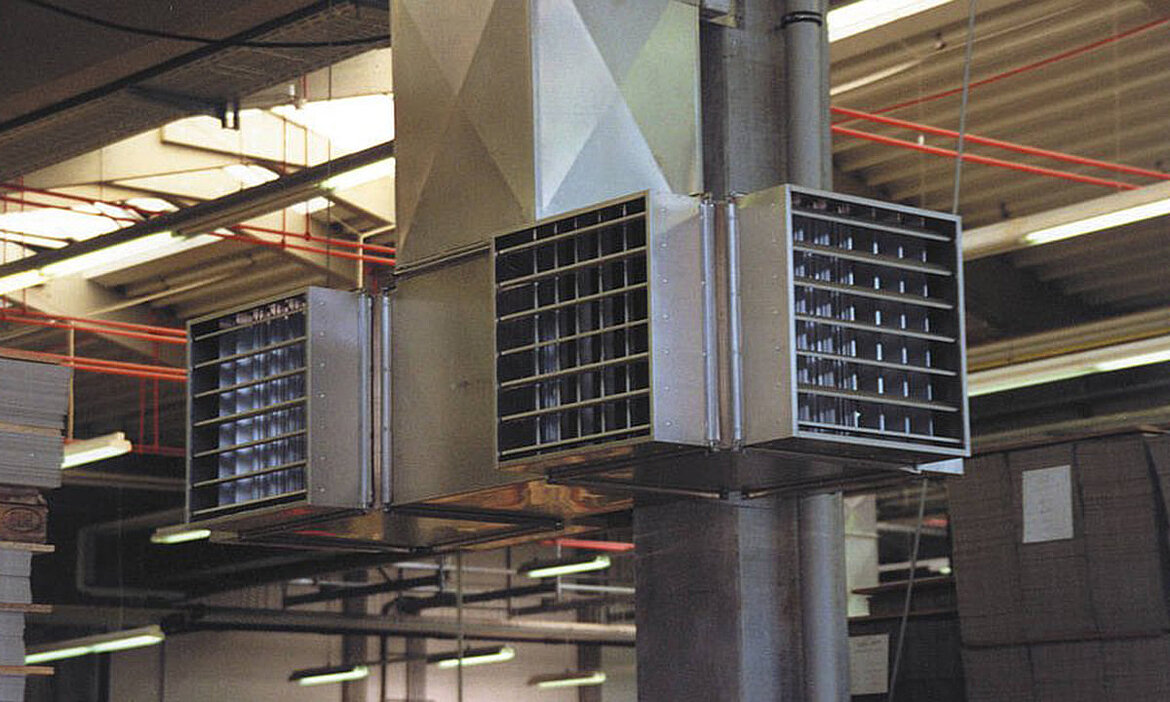

Decentralised ventilation system

Decentralised ventilation systems are only used for the ventilation of individual areas or rooms, not for the ventilation of entire buildings. In the case of the decentralised ventilation system, there is mainly an exhaust air system and a supply and exhaust air system.

With the decentralised exhaust air system, the rooms are connected to the outside world via a duct or an exhaust air shaft. A vacuum is created via a ventilator located in the system, which extracts the bad air. The supply air is provided by simple ventilation flaps or ventilation slots in doors.

The decentralised supply and exhaust air system works according to the same principle as the central ventilation system. However, both ventilators and all other necessary components such as filters or heating coils are integrated in the ductwork. The effort to install such a unit is therefore relatively low and can usually be carried out in the building.

Advantages of the central ventilation system:

- Energy savings can be implemented in winter

- Lower noise pollution than in decentralised systems due to centralised system components and appropriate soundproofing

- No danger of air short-circuit

- Air conditioning of the supply air possible

- Individual areas or rooms can be regulated

Advantages of the decentralised ventilation system:

- Retrofitting easy to implement

- Minor structural measures necessary

- Heat recovery can be used

- Cost-effective operation when ventilating fewer rooms

- Individual air control possible

Fresh air – the most important factor in the workplace

Air exchange and the associated fresh air in the work area play a particularly important role. In order to have optimal effects on the working day, the fresh air supplied should reach those working as cleanly, directly and unmixed as possible. Therefore, it should be placed as deep as possible in the building and as close as possible to the work area. This also has the great advantage that maximum ventilation can be achieved in the work area through a targeted air exchange with smaller air volumes. The stale air can be removed from the building with natural ventilation systems without additional operating costs due to the thermal lift.

Most effective ventilation system

Mechanical ventilation in combination with natural ventilation is one of the most effective and also most economical ventilation and aeration systems for most of the year. The ventilation system works with a targeted airflow and one or more ventilators. These ensure the required air exchange in the room or building – completely independent of external influences such as wind pressure or temperatures.

Advantages of controlled ventilation and aeration:

- Energy cost savings

- Increases the quality of the air and the quality of the time spent in the building

- Increases the well-being and performance quality of those working in the building

- Possibility for temperature monitoring

- Prevents mould growth

Mechanical ventilation systems can be designed as decentralised or centralised supply air systems for ventilation and, in winter, also for heating. In both cases, the type of air routing is decisive for optimum operating success.

Our products for mechanical ventilation

Learn more about our products